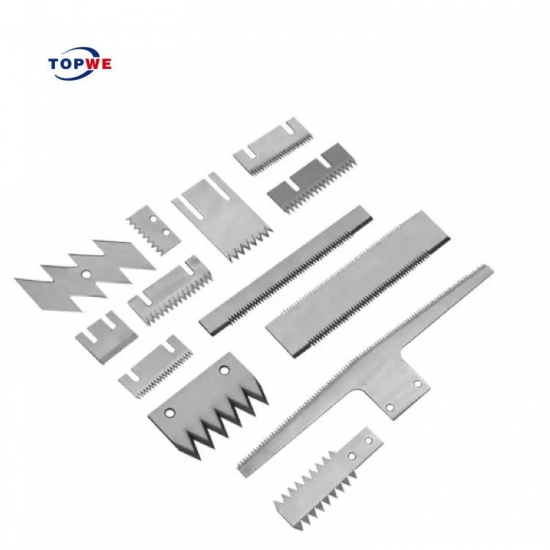

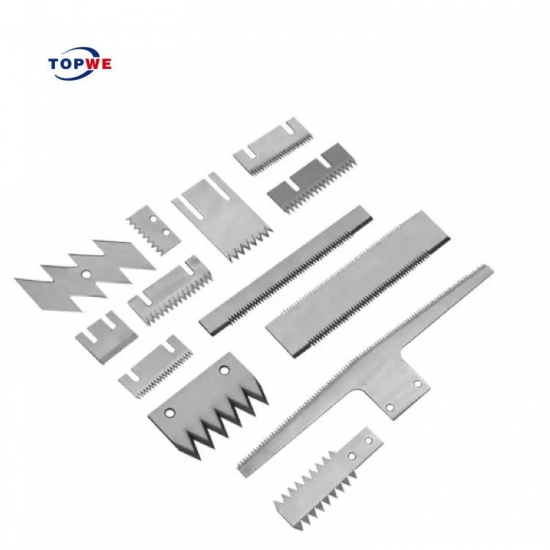

Packaging machine blades are essential components in various industrial and commercial packaging processes. These blades are designed to perform precise cutting, slitting, and trimming tasks, ensuring that packaging materials are processed efficiently and accurately. Here’s an overview of the key uses and importance of packaging machine blades:

1. Cutting and Trimming

Packaging machine blades are primarily used for cutting and trimming packaging materials, such as plastic films, paper, foil, and other flexible materials. The blades ensure clean, precise cuts, which are crucial for maintaining the quality and appearance of the final packaged product.

2. Slitting

In many packaging processes, large rolls of material need to be slit into narrower widths. Packaging machine blades are employed in slitting machines to divide these rolls into smaller, manageable sizes, ready for further processing or wrapping. This is particularly important in industries like food packaging, where precise material widths are required.

3. Perforating

Perforation is another common use of packaging machine blades. Perforated materials are easier to tear, which is useful for creating easy-open packages, vented packaging, or materials that need to be separated along perforated lines. This is commonly seen in products like plastic bags, labels, and films.

4. Scoring

Scoring involves making a partial cut or indentation in packaging material without cutting through it entirely. Packaging machine blades are used to create these score lines, which make it easier to fold or form the material into the desired shape, such as in the creation of cartons, boxes, or other folded packaging.

5. Sealing and Cutting

In certain packaging machines, blades are used to simultaneously cut and seal packaging material, such as in heat-sealing applications. This is common in food packaging where the integrity of the seal is essential for preserving freshness and preventing contamination.

6. Customization and Design

Packaging machine blades can be customized to create specific shapes or patterns, such as die-cut designs or custom edges on packaging materials. This is often used in creating unique packaging designs that stand out on the shelf, as well as in functional packaging features like tear strips or easy-open tabs.

7. Consistency and Speed

The use of

high-quality packaging machine blades ensures consistent performance in high-speed packaging operations. They are designed to maintain sharpness and durability over time, reducing downtime for blade changes and ensuring that production lines run smoothly and efficiently.

8. Material Versatility

Packaging machine blades are made from various materials, such as stainless steel, carbon steel, or tungsten carbide, depending on the specific requirements of the packaging process. The choice of material affects the blade's durability, sharpness, and suitability for cutting different types of packaging materials.

In conclusion, packaging machine blades play a crucial role in the packaging industry, enabling manufacturers to produce high-quality, well-packaged products efficiently. Their precision, durability, and versatility make them indispensable in ensuring that packaging processes are both effective and cost-efficient.

Network Supported

Network Supported